ICESNOW 3ton/day Flake Ice Maker energy-saving

Sub-cooled ice, excellent fast cooling Super cold, dry, crisp, 100% subcooled ice with greater surface area and exceptional cooling power.

Low maintenance and operation cost Super performance offers trouble-free operation, with much less maintenance probability than other brands of ice flaker.

Energy-efficient and cost saving

Pressure Swtiches and guage

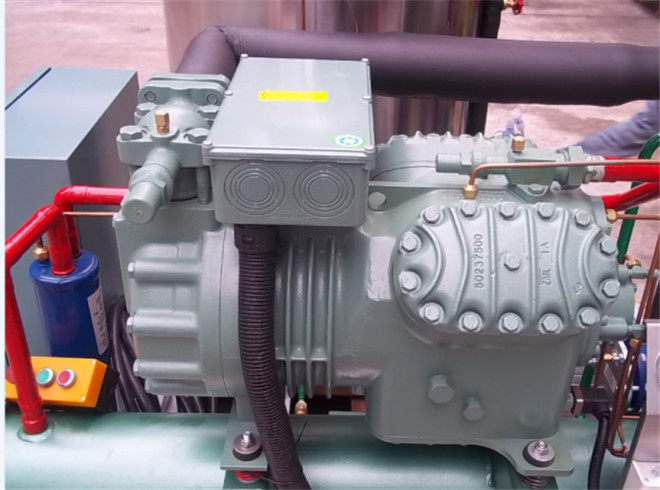

Germany brand Bitzer Compressor

Danfoss Expansion Valve

| Name | Technical Parameters |

| Model | GM-30KA |

| ice production (days) | 3000kg/day |

| Unit weight (kg) | 585Kg |

| Unit dimension (mm) | 1648mm×1450mm×1400mm |

| Dimension of ice storage room (mm) | 1800mm×2000mm×1800mm |

| Ice bin capacity | 1500kg |

| Thickness of ice flake (mm) | 1.5mm-2.2mm |

| Refrigerant | R404A |

| Installed total power | 11.4KW |

| Compressor | Semi-hermetic Bizter |

| Compressor horse power | 15HP |

| Flake ice temperature | -5--8℃ |

| cooling method | Air cooling |

1. Fishing--Sea water flake ice machine can make ice directly from the sea water, ice can be used in fast cooling of fish and other sea products. Fishing industry is the largest application field of flake ice machine.

2. Sea food process--Flake ice can lower the temperature of cleaning water and sea products, therefore it resists the growth of bacteria and keeps the sea food fresh.

3. Bakery--During the mixing of flour and milk, can prevent the flour from self raising by adding flake ice.

4. Poultry--Huge amount of heat will be generated in food processing, flake ice can effectively cool the meat and water air, also supply moisture for the products at the meantime.

5. Vegetables distribution and fresh-keeping--Now days, in order to guarantee the safety of food, such as vegetables, fruit and meat, more and more physical methods of storing and transporting are being adopted. Flake ice has a fast cooling effect so as to ensure the applied object will not be damaged by bacteria.

6. Medicine--In most cases of biosynthesis and chemosynthesis, flake ice is used to control the reaction rate and maintain the liveness. Flake ice is sanitary, clean with rapid temperature reduction effect. It is the most ideal temperature-reducing carrier.

7. Concrete Cooling--Flake ice is used as the direct source of water in concrete cooling process, more than 80% in weight. It is a perfect media of temperature controlling, can achieve effective and controllable mixing effect. Concrete will not crack if is been mixed and poured in constant and low temperature. Flake ice is widely used in the large projects such as high standard express way, bridge, hydro-plant and nuclear power plant.

(1) Be made of low-temperature pressure vessel special materials and passed precision processing;

(2) More sufficient evaporation area and better performance with dry style evaporation way;

(3) Whole processing is made by vertical lathe to ensure the precision up to 2 ounces;

(4) Be designed and produced with standard low-temperature pressure vessel manufacturing process, including surface treatment, heat treatment, gas-tight test, tensile & compression strength test, etc.

(5) Using imported refrigeration accessories;

(6) All water supply line are made of stainless steel, high sanitary condition;

(7) Fast ice forming & falling speed, ice begins within 1 to 2 minutes.

(8) Ice blade: made of SUS304 material seamless steel tube and formed through only one time process. It's durable.

(9) Spindle and other accessories: made of SUS304 material through precision machining, and conform to food hygiene standards.

(10) Thermal insulation: foaming machine filling with imported polyurethane foam insulation. Better effect.