Short Lead Time for Commercial Ice Cube Machine - less space Automatic direct cooling ice block machine ice maker 5 ton – Icesnow

Short Lead Time for Commercial Ice Cube Machine - less space Automatic direct cooling ice block machine ice maker 5 ton – Icesnow Detail:

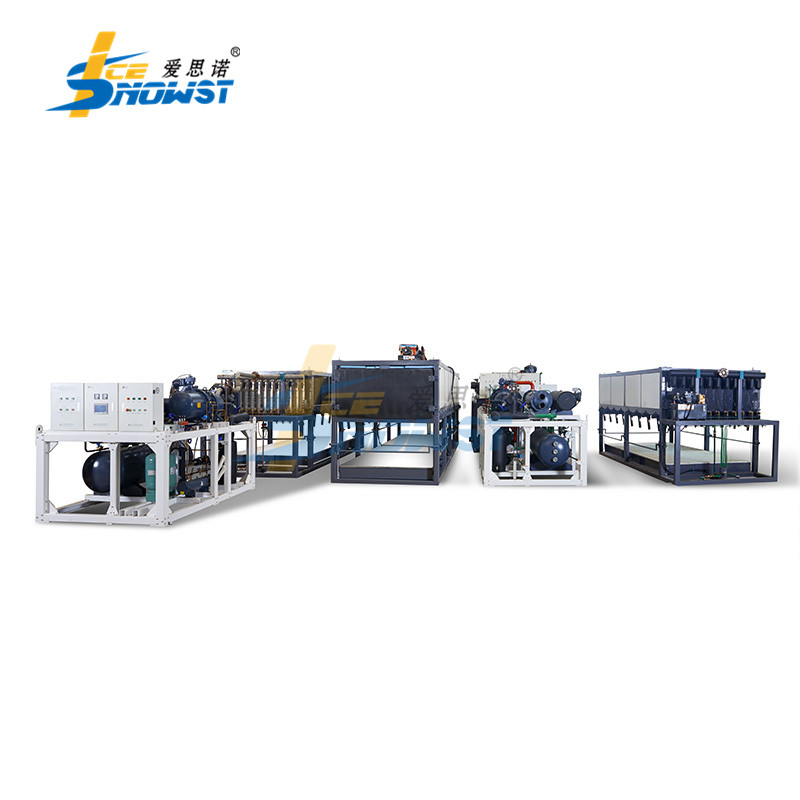

The direct cooling block ice machine is a block ice (ice brick) production equipment. The direct cooling ice machine evaporator adopts high-efficiency heat-conducting aluminum alloy material, which directly exchanges heat with the refrigerant, has low freezing temperature and fast ice making speed. Ice cubes melt slowly.

The direct cooling ice machine is highly automatic, automatic water supply, automatic ice making, automatic ice harvest, need no manual operation. The direct cooling ice machine does not need to use brine water. The ice mold does not need to be replaced after long time service. The equipment is safe and environmentally friendly, and the ice blocks are clean and hygienic, which can meet the food standard. Modular design, simple operation, small area occupation, easy installation, you can begin ice production as soon as connected to water and electricity.

1. The entire ice making system is modular in design and easy to operate.

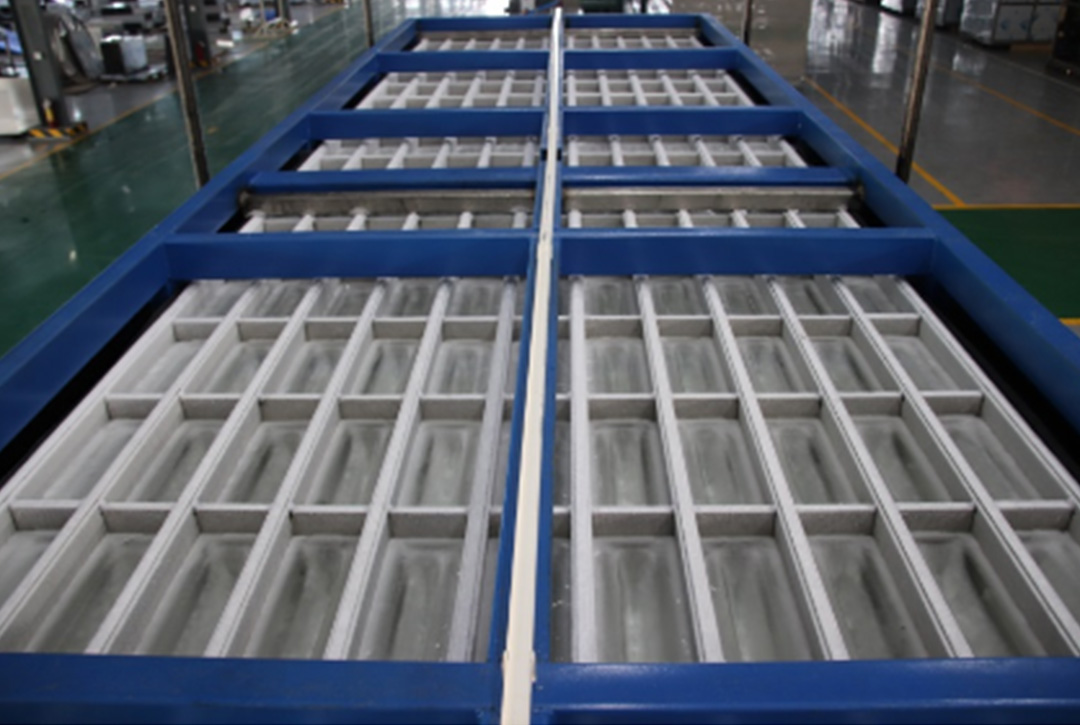

2. Efficient heat transfer: high-efficiency heat-conducting aluminum alloy material, unique evaporation aluminum plate design structure

3. High automation: automatic control of water, ice making and deicing of straight cold ice machine

4. Fast ice making speed: low freezing temperature, saving freezing time, quick freezing and freezing

5. The speed of deicing is fast, and the amount of ice loss is small.

6. Saving civil construction cost: the floor space is small, and the water can be connected to the water at the site.

7. The ice blocks are clean and hygienic: the water quality is up to standard and the ice blocks can be eaten.

(1). It’s evaporated directly without chemical or salt water,which is sanitary to edible.

(2). Adopt PLC program centralized control, auto water supplying and auto ice dropping.No need to use lift to harvest the ice blocks, save man power.

(3). Large production with beautifu,sanitary and clean ice blocks ,which are good for human consumption.

(4). Easy operation, convenient transportation, and take up little space with low cost .

(5). The material of ice moulds are Aluminum plate, mainframe adopts stainless steel, which is anti-rust and anti-corrosive.

(6). Excellent combination and the first-class refrigerant components of the world with the characteristics of high efficiency, energy saving and low noise.

Direct Ice Forming Method

The direct cooling ice block machine ice mold material is aluminum plate, the main machine is made of stainless steel, which has the characteristics of anti-rust and anticorrosion.

Equipped with an electic lift to speed up the collection of ice.

Auto Control System

The machine is using Siemens PLC and touch screen controller for system control. After very short learning, operator may get to handle the whole machine

Bitzer Compressor

Germany Bitzer is a world famous brand, its after-sales service centers are all over the world. And the quality is on the top of the area We have more than 15 years of experience using Bitzer compressor in our ice mchines.

PLC control system with touch screen:

we used PLC programmable control system to control our ice machine, so it is easy operation, no person need monitor the ice machine, and also it can reduce the failure rates, so as to ensure that the ice machine controlled reliably , operated stably with lower problem occurrence and easily maintenance. which will save your cost and save your time.

the PLC can control such as:high/low pressure alarm, oil pressure alarm, compressor overload, fan overload, agitator overload, control solenoid valve and so on.

Touch screen automatic control system:

monitoring ice machine operation, timer on and off ice machines, recording ice machine operation automatically, it can accurately detect causes of failure and find solutions when the ice machine fails, which is easy for customers to use and maintain.

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for Short Lead Time for Commercial Ice Cube Machine - less space Automatic direct cooling ice block machine ice maker 5 ton – Icesnow , The product will supply to all over the world, such as: Milan, Bangladesh, Los Angeles, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to provide customers with high quality products, provide high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.